The Standen T3 Harvester is a tractor trailed 3-row potato harvester offering up to 60% more output than a 2-row trailed harvester. The T3 has a large digging area and sieving webs plus a huge capacity version of the OMEGA fluted roller separating system so it is well equipped to handle large outputs.

The Standen T3 Harvester has the ability to harvest on a 72" wheel track (1.8m beds), lifting one pair of rows between the tractor wheels plus 1-row from the right or 1-row from the left bed. Or at 108" (2.75m) tractor wheel track, 3-rows at 36" (90cm).

Built for Strength and Reliability

The T3 is built on a heavy duty chassis designed to provide strength, superb driver visibility and easy maintenance access. The drive-line is simple and robust requiring minimal attention with long life components to maximise reliability. All hydraulic variable speed drives are featured throughout the harvester with speeds adjustable from the cab mounted control box.

In-Cab Control System

Touch screen technology comes as standard on our easy to operate in-cab control system. Profiles can be created offering a fast selection of a range of settings to suit different crops and conditions. A series of functions can also be programmed to operate in sequence, for example at the start or at the end of the rows to be lifted.

Efficient but Gentle Cleaning & Loading

Efficient elevator loading is ensured by the 3 x spreader webs as the cleaned crop is gently and evenly spread across the width of the discharge elevator. A high capacity 1.3m wide elevator is well matched to the harvester’s capacity and large soft rubber flights mean the elevator can discharge slowly and gently. It also has sufficient reach to gently lower the crop into large capacity trailers. Double articulation allows the elevator to be lowered sufficiently to gently windrow the crop and to fold easily into the 3.4m transport width.

Manouverable and Versatile

The Standen T3 Harvester can be ready for the road in seconds as the driver can rotate the offside wheel underneath the harvester for road transport to achieve a transport width of 3.4m. Opening of the field is carried out with the wheel under the harvester; sensors automatically reverse its driven direction when its position is changed. Once the crop is opened the wheel is simply rotated to its outer position for maximum harvester stability. A special wide angle P.T.O shaft allows the powered axle operation at headlands when turning tightly.

VariSep Technology: control of separation point between webs

VariSep enables the operator to easily increase or decrease degree of separation. Separation can be set for maximum separation (high step) or minimum separation level webs (no step). This helps the operator easily adjust the machine according to the conditions in each part of the field to minimise potential crop damage. A hydraulically driven rubber covered haulm roller provides effective haulm removal, this full width roller can be reversed from the in cab controls and is spring loaded for stone protection.

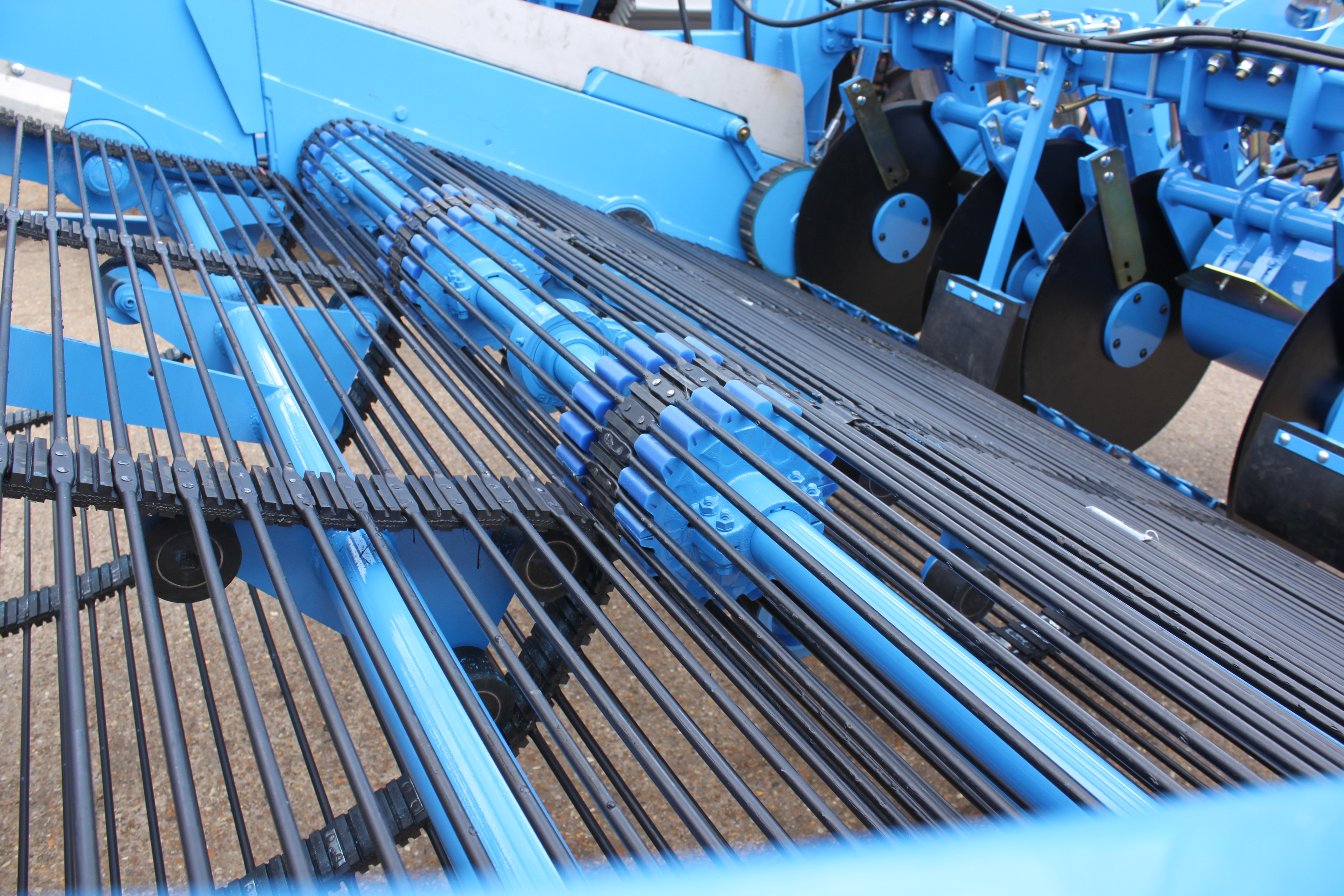

OMEGA: Advanced Separation Technology

The Standen T3 Harvester features 2 OMEGA separating units, one behind the other, provided class leading separation capacity 'per row' to outperform other machines. Each unit comprises of: 4 x soft fluted air pocket scroll rollers and 4 x clod rollers; Rubber or steel. Both OMEGA units are angle adjustable from the cab to provide varying degrees of separation. Fluted scroll and clod roller speeds and clod roller height are adjustable from the drivers cab. Clod rollers can also be reversed. During adjustment each clod roller rotates around the circumference of their adjacent fluted roller. This unique 'constant geometry' design ensured the gap doesn't change with up/down adjustment. OMEGA's wide range of adjustment enables it to be effectively used in many different soil types and conditions.

The T3 Harvester is built to order and made to your own specification.

Suitable for use on salad and main crop potatoes, carrots, onions, parsnips, turnips, celeriac and more.

Get in touch for more information.