International Terms and Conditions of Sale

General Supply Conditions for the supply of machines, installations and solutions

Valid from 01/08/2020

The present General Conditions shall apply, save as varied by express agreement in writing by the contractual parties.

Wherever the present General Conditions use the term “in writing”, this shall mean by documents signed by the two parties or by letter, facsimile, electronic mail or by such other means agreed to by the parties.

For agreements between contractual parties to be valid, they must be in writing.

In case of divergent interpretations of the English text and the text drawn up in the other language, the English shall prevail.

1. General Provisions

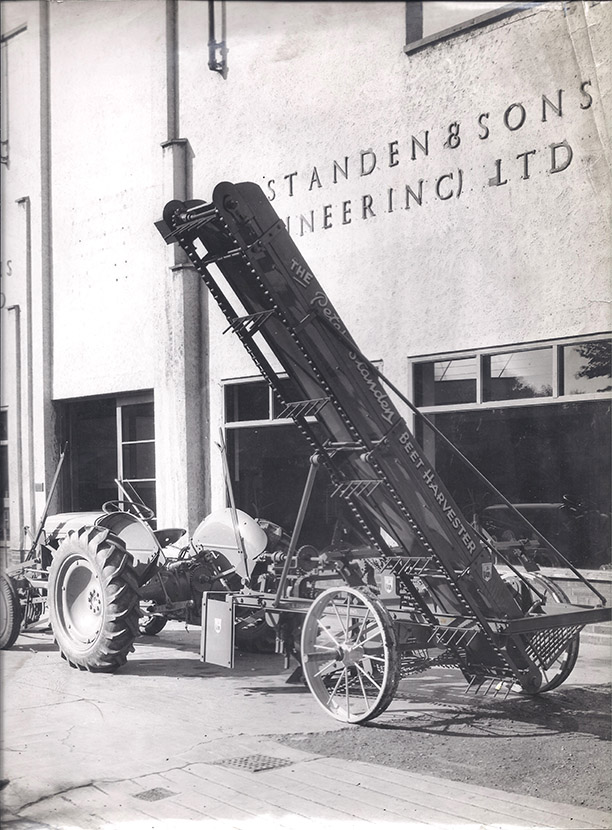

The sale of our goods is carried out in accordance with the present general conditions, and the purchaser recognises to have full knowledge of the terms thereof. Any derogation from these general business conditions shall only be valid after express written agreement. The catalogues, printed matter and other commercial or technical documents belonging to Standen Engineering Ltd excluding the present general conditions, may in no case be considered as contractual. They may be modified without prior notice. It is not for us to assess the appropriateness of the choice of products, objects or goods regarding the final use by the client. Consequently, the company Standen Engineering Ltd, shall in no case be held responsible for side effects arising from the use its products under conditions or circumstances other than the normal or reasonably foreseeable conditions of use.

2. Formation of contract

2.1 The contract is deemed to be entered into when the seller has sent a written acceptance upon receipt of an order, if need be, within the deadline set by the purchaser.

2.2 If, on submitting a written offer, the seller has set a deadline for acceptance, the contract is deemed to be entered into if the purchaser has sent a written acceptance prior to the expiry of the deadline. However, this is only valid if such declaration of acceptance arrives no later than one week after such deadline has expired.

3. Plans and documents

3.1 The indications contained in the catalogues, leaflets, circulars, advertisements, illustrations and price lists relating to weight, measurements, volume and other data are not legally binding save to the extent that, under the terms of the contract, it is expressly stated that they are binding. This is valid also for indications and information contained in general documents relating to the product and in price lists – whether they are in an electronic or other type of format.

3.2 The plans and technical documents that are submitted to the purchaser in person prior to or following the conclusion of the contract or are put at their disposal in electronic format and that may be used for the construction of the goods that are the subject of the delivery or of different parts thereof shall remain the exclusive property of the seller. Without its agreement, the purchaser shall not be authorised to use, copy, reproduce or hand over to a third party, nor let a third party have knowledge of them.

3.3 Drafts, drawings, and documents of any kind submitted or used by the seller remain its exclusive property. They should be returned to it at its request. They are provided free of charge, if they are followed by an order relating to them, otherwise reimbursement of costs and travel expenses shall be due to the seller. The seller retains full intellectual property of its drawings and documents, and these may not be communicated nor carried out without its written authorisation.

4. Packaging

If not stipulated in the sales contract.

4.1 The prices quoted in the price lists and catalogues shall be deemed to be exclusive of packaging.

4.2 The prices quoted in the legally binding offers and in the contract include the packaging or protection required under normal transport conditions in order to prevent damage to the goods that are subject of the delivery before they reach the palace of destination as stated in the contract.

5. Risk Transfer

5.1 The time at which the risk shall pass is determined in accordance with the international rules for the interpretation of trade terms (incoterms) of the International Chamber of Commerce using the version in force at the date of the formation of the contract. Where no indication in the contract of the form of sale, the goods which are the subject of delivery shall be deemed to be sold “ex-works”.

5.2 In the case of a sale of ex-works, the seller must provide the purchaser with written notification of the date on which the purchaser must take delivery of the goods. Such notification must be given in sufficient time to allow the purchaser to take such measures as are normally necessary for the purpose of taking delivery.

5.3 If, in the case of a sale ex-works, the seller, at the purchasers’ request, undertakes to send the goods to their destination, the risk will pass to the purchaser at the time of the handing over [of the goods] to the first carrier. insofar as this moment precedes the moment defined in article 6.2.

5.4 If, in the case of a sale ex-works, the purchaser does not collect the goods that are the subject of the delivery due to one of the situations stipulated in article 7, the risk passes to the purchaser at the latest at the time the said situation occurs.

6. Delivery time, Transport and Loading

6.1 Final validation of the order and calculation of delivery time may be made after receipt by us of the signed order acknowledgement and of any duly mentioned advance payment. Any delay shall lead to the delivery being postponed accordingly. Should the interim terms not be met, delivery of the equipment may be postponed accordingly.

6.2 Should no choice be expressed by the client, the choice regarding the means of transport and the choice of carrier shall be made exclusively by the company Standen Engineering Ltd. Our delivery periods are indicative and any delay therein cannot be a justification for any refusal of goods, order cancellation or any indemnity whatsoever on behalf of the purchaser. Goods, including goods sent post paid, are always transported at the recipients own risk. In the case of damage in transit, shortages etc, specific reservations must be made on the carrier’s delivery receipt and be confirmed by registered letter within the time provided by law.

6.3 In the case of collection by the client.

6.3.1 If the purchaser fails to accept delivery of the goods at the contractually agreed time, he shall nevertheless pay the purchase price which becomes due on delivery as if delivery had taken place. The seller shall, if he is in a position to do so, store the products at the expense of the purchaser. The purchaser shall insure the products at his own expense.

6.3.2 The loading shall be carried out by the seller at the expense of the purchaser at the rates currently in force. Where transportation is provided by us, unloading onto the quay, handling, storage and insurance of materials at the client’s premises outside or within the factory are at the cost and under the responsibility of the purchaser.

7. Start-up of equipment

7.1 In the case In the case of an order on behalf of the client for a start-up, the purchaser undertakes, as from the agreed delivery date for the equipment, to have the necessary equipment at its disposal (e.g., a tractor).

7.2 The purchaser shall be solely responsible for the choice of tyre and load bearing capacity on his own equipment.

7.3 The seller may not be held responsible for meteorological and bad weather conditions that make start up impossible. In such an event, the seller is not obliged to wait for a possible lull. A second technical mission may be arranged with the agreement of both parties.

7.4 The start-up in the field must be carried out in normal conditions, with normal vegetables and normal foliage. Any possible additional time necessary for the start up in conditions judged to be unusual by the seller will be charged to the purchaser according to our current rates.

Payment

8.1 The purchaser must make all payments with the agreed payment conditions.

8.2 Any advance payments made by the purchaser shall be deducted from the price of the delivery. They shall not constitute a deposit, the abandonment of which would entitle the purchaser to terminate the contract.

8.3 Should the purchaser be late in payment, the seller shall be entitled to cease to fulfil its own obligations until receipt of the corresponding amounts, save where the late payment is based on an action or omission on the part of the seller. The seller is entitled to withhold its service if, due to a circumstance occurring after the contract has been concluded, it considers that it may not receive the purchaser’s consideration in its entirety and under the agreed conditions.

8.4 Payment of our invoices shall be made to our head office at Ely on the agreed due date as mentioned on the order. The rates applicable are those in effect on the date the order is made. No discount shall be made for an advance payment. If payment is made by cheque, this must be in the possession of the company Standen Engineering Ltd on or by the due date indicated on the invoice or order confirmation. Payment conditions may in no case be unilaterally modified by the client, without written consent of the company Standen Engineering Ltd.

8.5 If the purchaser is late with its payment, the seller may demand default interest. In the case of payment after the payment date indicated on the invoice, penalties for late payment calculated at the legal interest rate plus 3% will be applied. The non-payment of all or part of the invoice by the due date shall make all other invoices due immediately, including those for which the time for payment has not yet expired. If, on a previous order, the purchaser backed out of one invoice by the due date shall make all other invoices due immediately, including those for which the time for payment has not yet expired. If, on a previous order, the purchaser backed out of one of its obligations (e.g., default payment or late payment) a refusal to sell may be made against it, unless the purchase can provide satisfactory guarantees or payment in cash. No discounts shall be made for payments in cash or advance payments.

8.6 If the purchaser does not pay the amount due within the 1-month deadline, the seller shall be entitled to terminate the contract by simple written notification (without referring to the court) and may claim damages.

8.7 Resolutory Clause

In the case of failure by the client to pay the amounts due by it on the due dates or to carry out any of its obligations, the company Standen Engineering Ltd may opt either to fulfil this contract for its duration, or to terminate the contract. In all cases, the sums paid as advance payments or interim payments shall remain his property in exchange for works carried out. In addition, the company Standen Engineering Ltd reserves the right to claim compensation for prejudice suffered following the non-fulfilment by the purchaser of its obligations.

9. Warranty

9.1 The warranty period shall begin to run on the day the purchaser receives delivery of the goods and will run for a period of 12 months from the delivery date. In the case of a sale to an authorised Standen Engineering Ltd dealer the warranty period runs for 12 months from the date of the initial sale by the dealer.

9.2 For spares parts delivered or parts repaired in pursuance of this article, the same warranty conditions shall be valid as for the goods which are the subject of the original delivery with the new warranty period of 12 months. For the other parts which are the subject of the delivery, the warranty period shall be extended only for the period during which the subject of the delivery has been immobilised due to a defect covered by this article.

9.3 The purchaser is required to immediately notify the seller in writing of any defects that have appeared. In all cases, such notification of defect must be made within a reasonable period after the end of the warranty period. The defect must be described in the notification of defect. If the purchaser does not send a written notification of the defect to the seller in the time specified in this article, the purchaser shall lose all claims to the relating to the remedy of the defect. In the case where the defect may possibly result in damage, the purchaser must immediately inform the seller in writing. The purchaser shall bear the risk for the damages that may result from omitting to send such information. The purchaser must give the seller every opportunity to record a defect and to remedy it.

9.4 After receiving notification of defect (article 9.3), the seller must remedy the defect forthwith at his own expense. On principle, the defect must be remedied on the place where the subject of delivery is situated, however the seller may, if he judges necessary, have the subject of delivery returned to him for the purpose of repairing or replacing it. The seller is responsible for dismantling and reassembling the part insofar as special knowledge is required for such action. Where no particular knowledge is required, the seller’s obligation as regards the defect shall cease at such time as the property repaired or replaced part has been delivered to the purchaser.

9.5 If no conflicting provision has been agreed to, the purchaser shall bear the cost and risk of transport of the defective parts, repaired parts or spare parts between the place of business and the place where the purchaser has returned the object at the purchaser’s request.

9.6 The seller’s warranty shall only apply to defects that appear under conditions provided for in the contract and under proper use. In particular, it does not cover defects arising from the purchaser’s faulty maintenance, or alterations carried out without the seller’s consent in writing, or from repairs carried out improperly by the purchaser, nor does it cover normal deterioration.

9.7 From the time at which the risk has passed (article 5), the seller shall bear no further responsibility other than that set out in this article.: this provision also concerns defects existing at a time prior to the transfer of risk. It is deemed to be expressly agreed that the seller is not obliged to pay the purchaser any damages for the damage of goods that is not the subject matter of the contract or for loss of profit unless it is shown by the circumstances of the case that the seller has been guilty of gross misconduct.

9.8 Gross misconduct does not comprise any and every lack of proper care or skill, but means an act or omission on the part of the seller implying either a failure to pay due regard to serious consequences which a conscientious contractor would normally foresee as likely to ensue, or a deliberate disregard of any consequences of such act or omission.

10. Damages

All claims by the purchaser, in particular concerning compensation for damages of all kinds are excluded – irrespective of the legal reason invoked to assert them.

11. Claims following receipt of goods

For claims to be admissible they must be made within 10 working days following receipt of goods and works, after this time, they will be considered to be null. Nor shall we be liable, even before the expiry of this deadline, once the goods have undergone any kind of alteration and are no longer in the condition in which they were delivered by us. Goods returned shall only be accepted following the prior written agreement of the company Standen Engineering Ltd. They shall be made at the purchasers risks and within 10 working days following the prior written agreement of the company Standen Engineering Ltd. They shall be made carriage paid unless otherwise agreed beforehand in writing by our company.

12. Scope of present conditions

The drawing up of the contract constitutes the clients pure and simple acceptance of the present conditions of sale, that shall if need be prevail over the clients purchase conditions, or any other document issued by him.

13. Termination of the contract

The termination of the contract, regardless of the reason invoked, shall not imply the loss of rights of the parties that are born during the term of validity of the contract up until the termination of such contract.

14. Arbitration and applicable law

14.1 All sales concluded by the company Standen Engineering Ltd shall be governed by the law of England and Wales. In case of disputes arising in respect of the performance of a sales contract or of the payment price, as well as in the case of interpretation or execution of the clauses and conditions set out above, the commercial court of London shall have sole competence, regardless of the place of delivery, the means of payment accepted and even in the case of the guarantee being called or proceedings involving several defendants.

14.2 In accordance with the rules of conciliation, and arbitration of the London Court of International Arbitration, final decisions relating to any litigation resulting from this contract shall be taken by one or several arbitrators designated in accordance with the said rules.

14.3 The contract is contingent upon the right of the seller to the extent that the parties have not expressly agreed to a different ruling.

14.4 The arbitration tribunal shall meet at the defendant’s head office to the extent that the case may not be duly dealt with by way of written proceedings. The proceedings shall be held in the English language.

14.5 The arbitrator shall, in giving their ruling, act as amiable compositors only if the parties expressly so agreed.

14.6 To the extent that the legal order that has been designated requires it for the recognition and enforceability of arbitral decisions and judgements made at the head office of the party concerned, the parties shall enter into a specific arbitration agreement satisfying the designated legal requirements and in which the rules of arbitration shall be set out in accordance with article 14.2

15. Unforeseeable circumstances or force majeure

The occurrence of a case of force majeure shall have the effect of suspending the fulfilment of the company Standen Engineering Ltd.’s contractual obligations. A case of force majeure means any event outside the control of the company Standen Engineering Ltd and that prevents it from functioning normally in terms of manufacturing or delivering the products. Total or partial strikes that effect the performance of the company Standen Engineering Ltd, or of one of its suppliers, sub-contractors or carriers shall be considered cases of force majeure, as in an interruption in transport, energy supply, raw materials or spare parts.

16. Retention of title

The company Standen Engineering Ltd shall reserve the title of goods sold until receipt of full payment of their price (principal and interests) Failing payment of the price at the agreed payment date, the seller may recover the goods, the sale shall be cancelled with full rights if the company Standen Engineering Ltd should see fit and the advance payments already paid shall remain his property in return for the full use of the goods that the purchaser will have had. The purchaser shall become responsible for the goods as soon as they are handed over, the transfer of ownership meaning a transfer of risks.